Spin Master Work Sample

Project 1 : Dive Characters

Project 2: Bottle Splash

Motivation

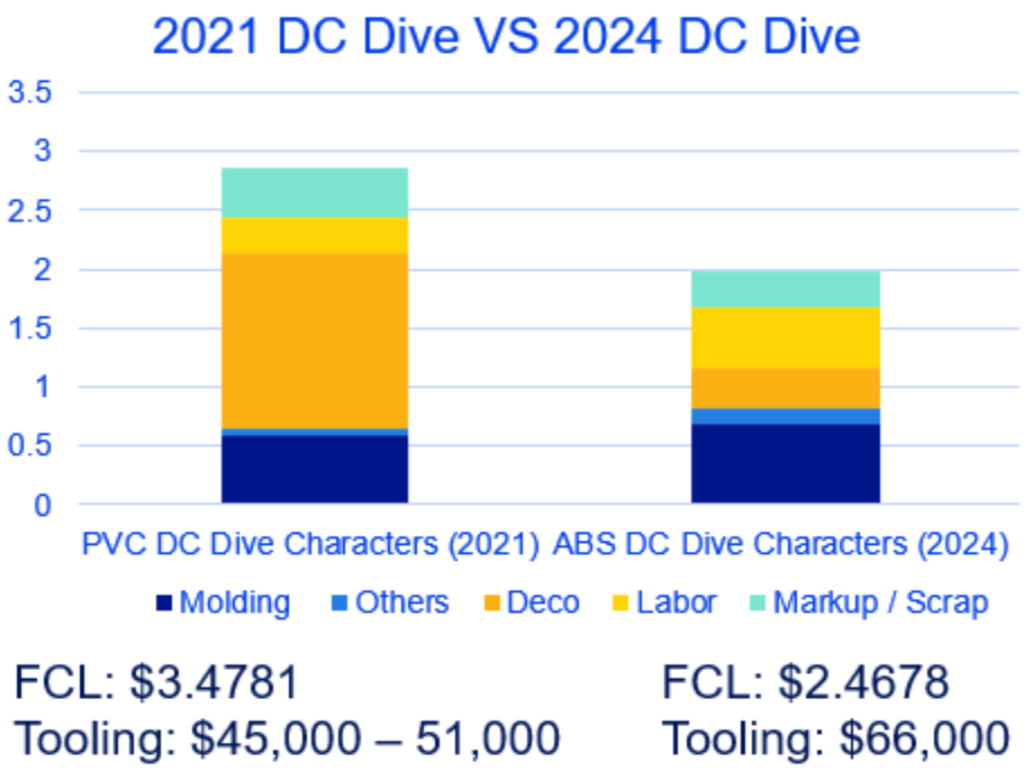

Dive Characters have been a core part of the Swimways licensed business for years. Although one of the hottest selling items in the line, over the years they have become more expensive and less profitable. In an effort to restore profitability and protect the legacy of the line, I was asked to explore cost reduction opportunities that would have negligible impact on consumer perception and experience for the new Spring 2024 additions.

Dive Characters

Priorities

Reduce cost by 30%

Maintain a 3 pack of figures

Maintain recognizable licenses

Maintain the overall size of the figures

Maintain or improve the quality

Initial Construction

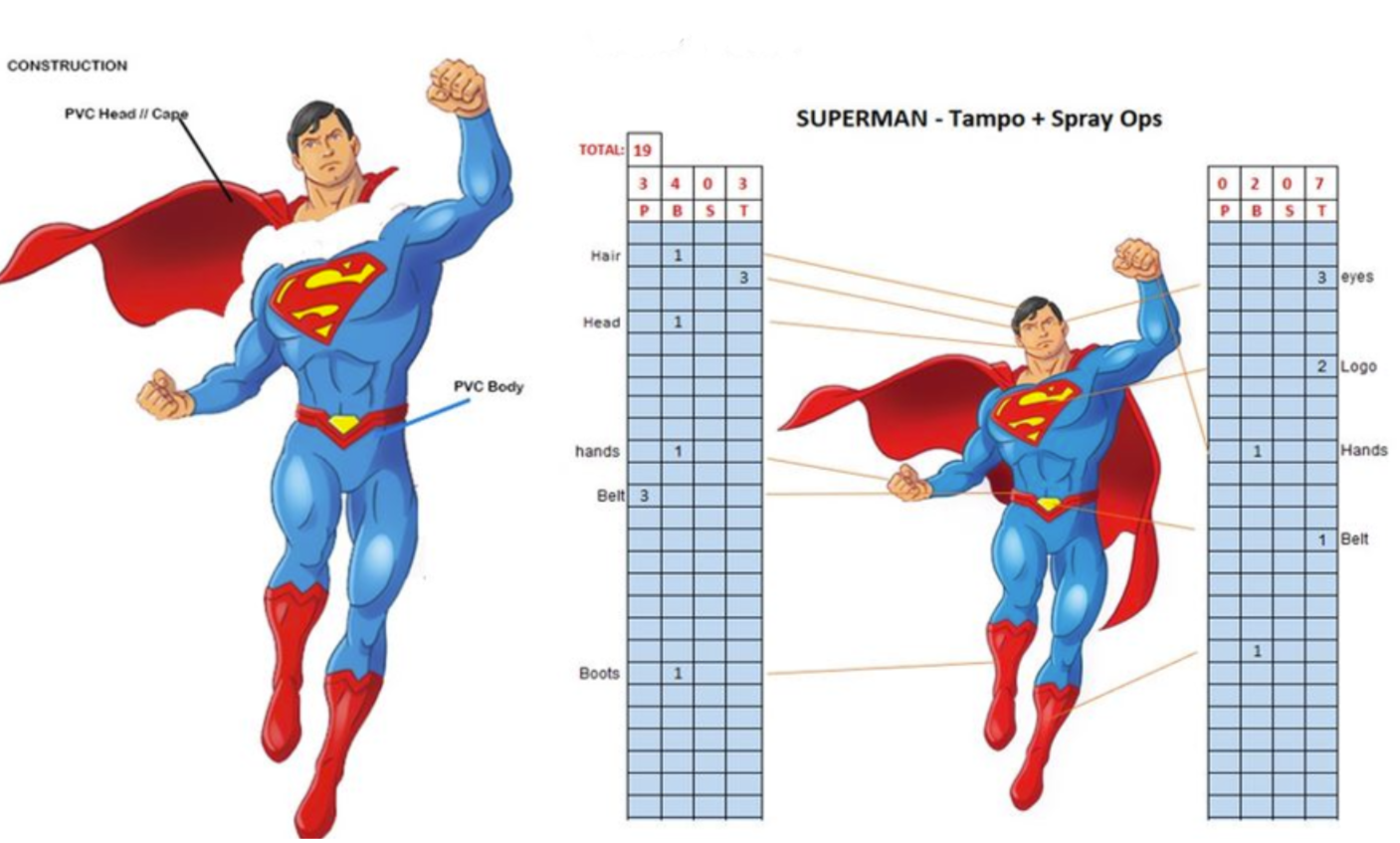

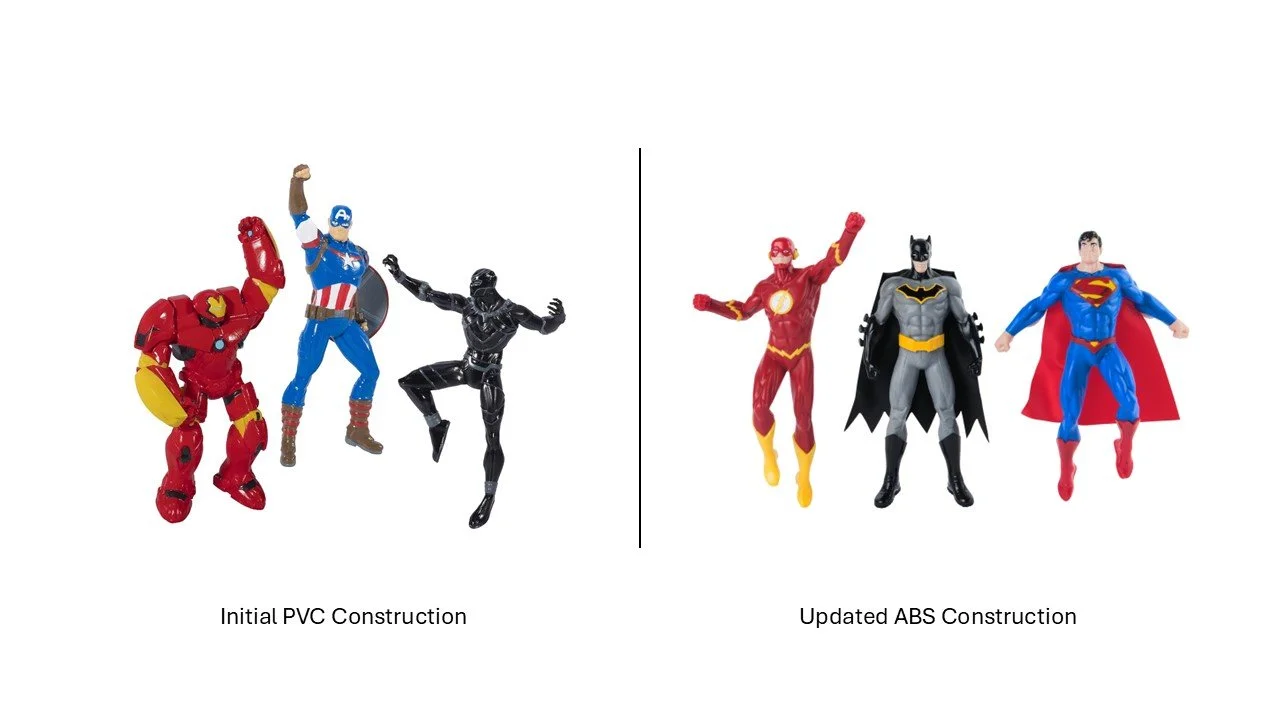

Initially, the dive characters were injection molded as a solid PVC character and decorated using pad printing and spray operations. The high material use and complex decoration methods made the character cost increase dramatically as PVC and labor costs increased.

The diagram to the right shows an example of how a character would have been created and the decoration labor associated.

Solution

To combat the main cost drivers (decoration labor and material usage), the assembly and manufacturing method was updated.

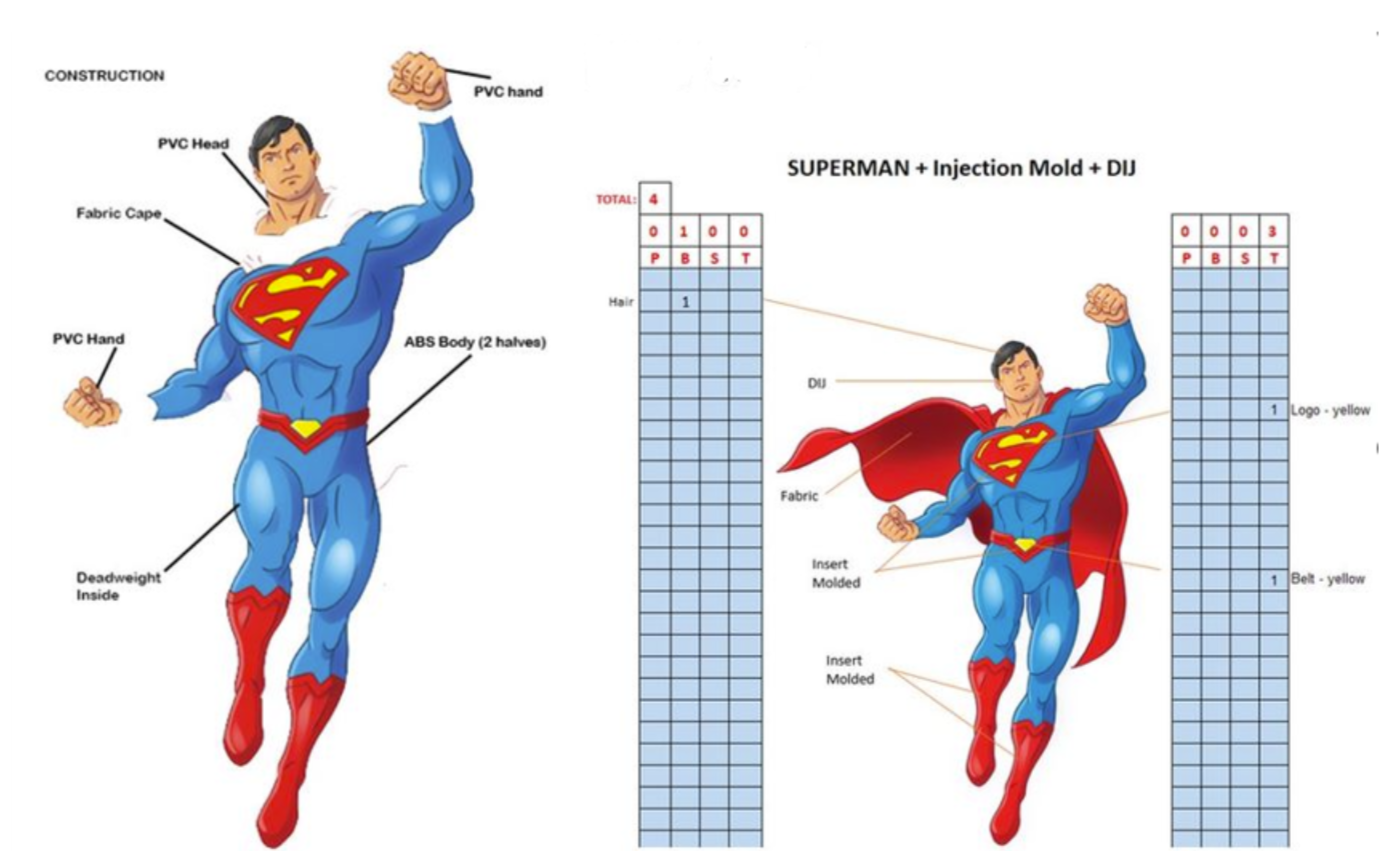

The Spring 24 line of characters leverage ABS insert-molding and DIJ printing. By switching the construction of characters from solid PVC to 2 halves ABS, the material usage was greatly decreased. Additionally, by using over-molding techniques and DIJ printing for the face, the cost of decoration labor was greatly reduced.

The diagram to the right shows the new construction method and subsequent deco operations. In this example, the decoration operations needed were reduced from 19 to 4.

Considerations - DIJ Printing

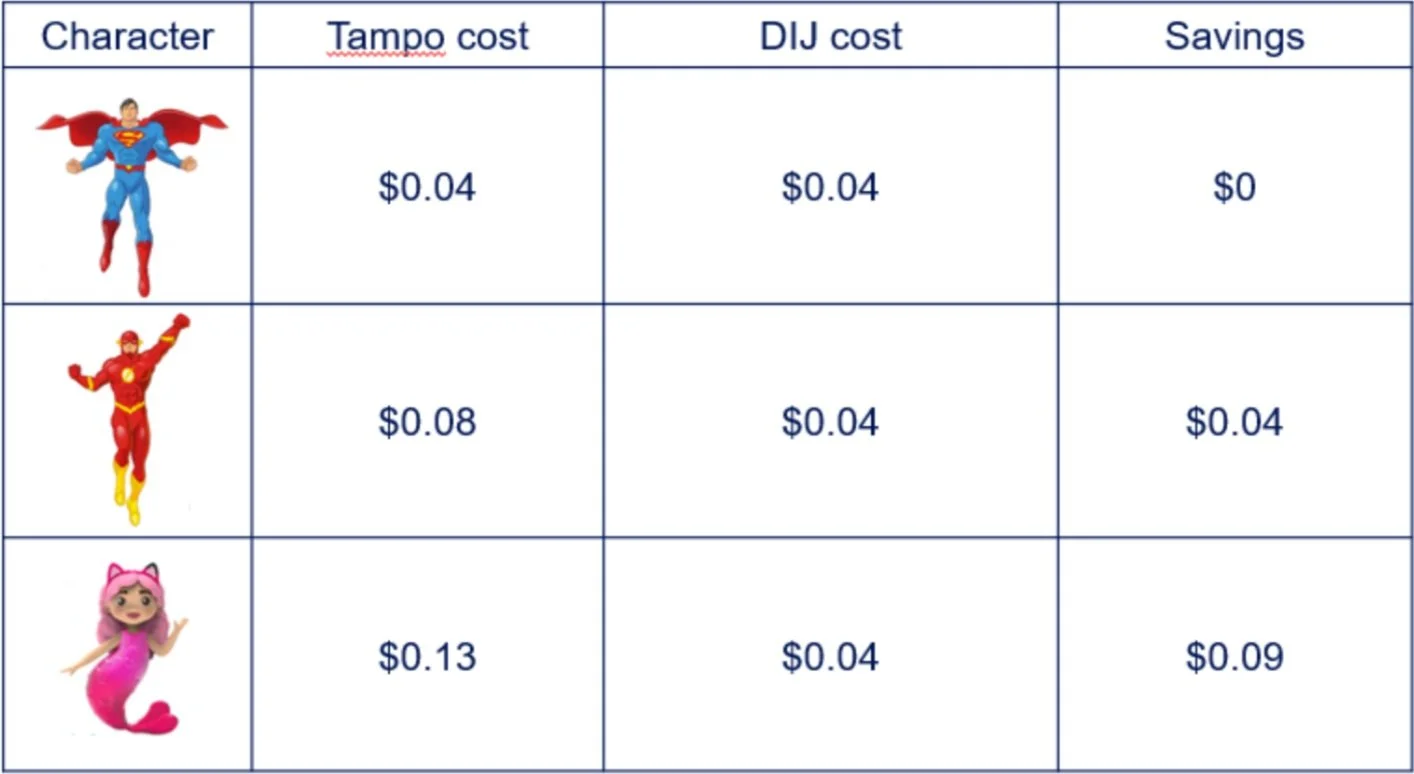

To best leverage DIJ printing, I had to consider the geometry of the face. For characters with flat faces, DIJ printing worked very well however it was unable to meet quality expectations for characters with more complex features.

After assessing potential cost savings and changes required to make figures suitable for DIJ printing, I decided whether to move forward with DIJ printing or continue tampo printing on a model by model basis.

Considerations - Insert Molding

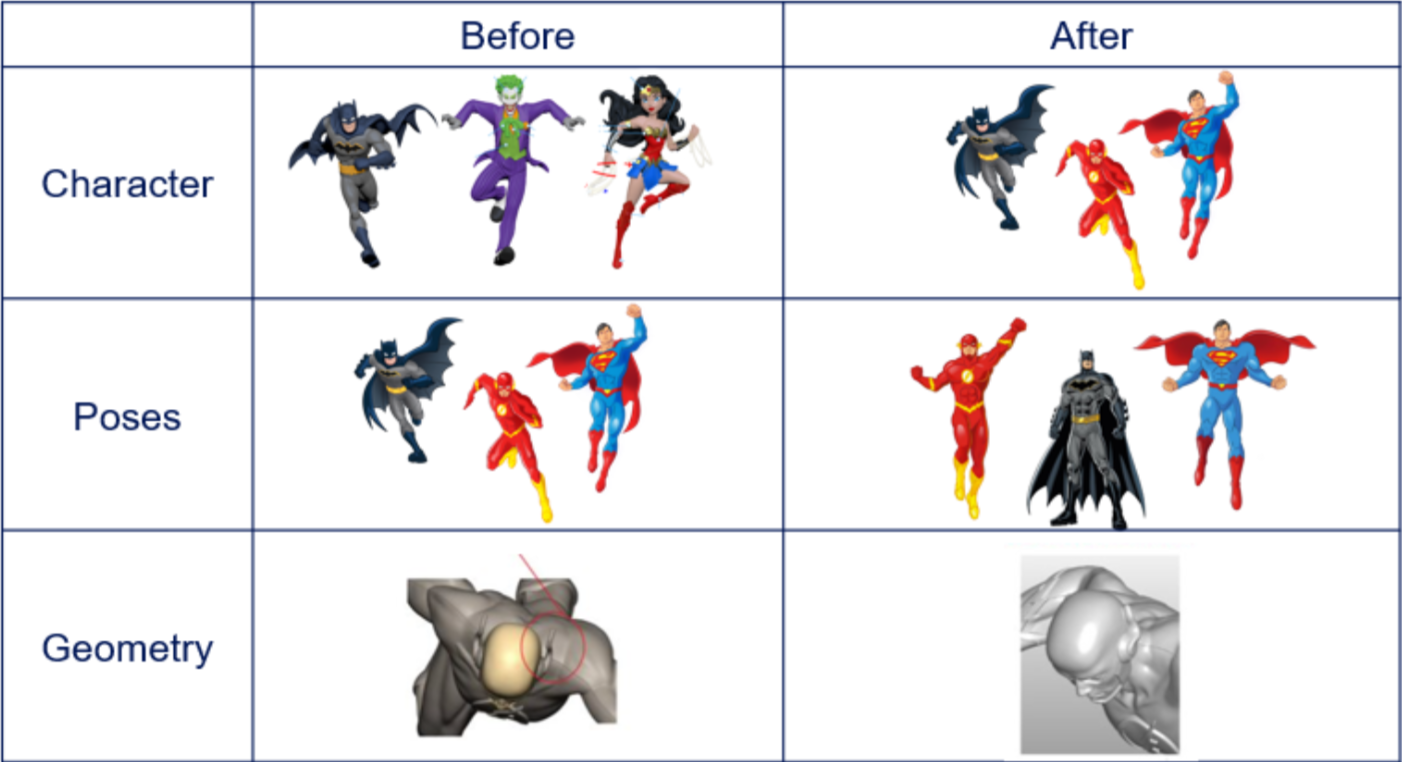

By changing the manufacturing method and materials of the characters, different design considerations were needed. For insert molding, I had to consider things like character choice, poses, and geometry.

For characters, I worked with the design team to choose characters that had 2-color-dominant designs. These characters were best suited for the new method because most of the decoration would be finished as soon as the parts came out of the mold, leaving only smaller detailing for hand operations.

For poses and geometry, molding considerations were taken into account to avoid undercuts. This meant altering poses and geometry of the sculpts for front to back molding.

Finally, although these changes saved a lot in decoration and material use, the molds needed for insert molding were significantly more expensive. Thus, I had to work closely with the brand team to ensure that the models would be manufactured in sufficient quantity to justify the capital expenditure on new molding equipment.

Results

Overall, I reduced the cost of the Spring 2024 dive characters line by 29%. I did this without sacrificing size, product offering, or quality. There was also a significant improvement in decoration quality and placement accuracy due to decreased use of hand detailing in the manufacturing process.

In addition to reducing the cost for the Spring 2024 line, my manager has confirmed that my updated process will also be applied to the dive character line additions in seasons to come.

2. Bottle Splash

Motivation

Bottle Splash was a concept that had been in development for 2 years prior to my arrival at Spin Master. The development was delayed because the product could not be reduced to a profitable cost. I inherited the project and was tasked with refining the design for the new season.

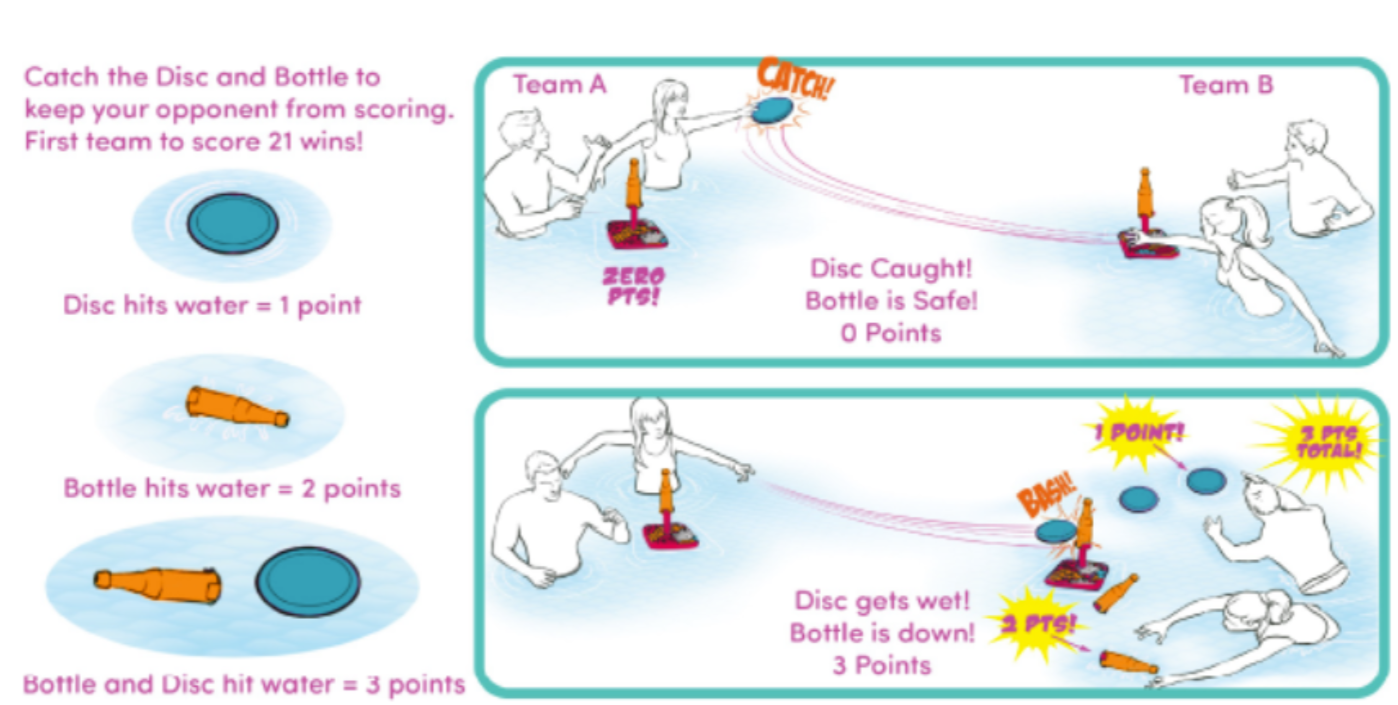

The original version of this item and play pattern in shown below

Priorities

Reduce cost by 6.4%

Fully waterproof components

Include all components for a full game

Maintain brand identity through high quality graphics

Exploration

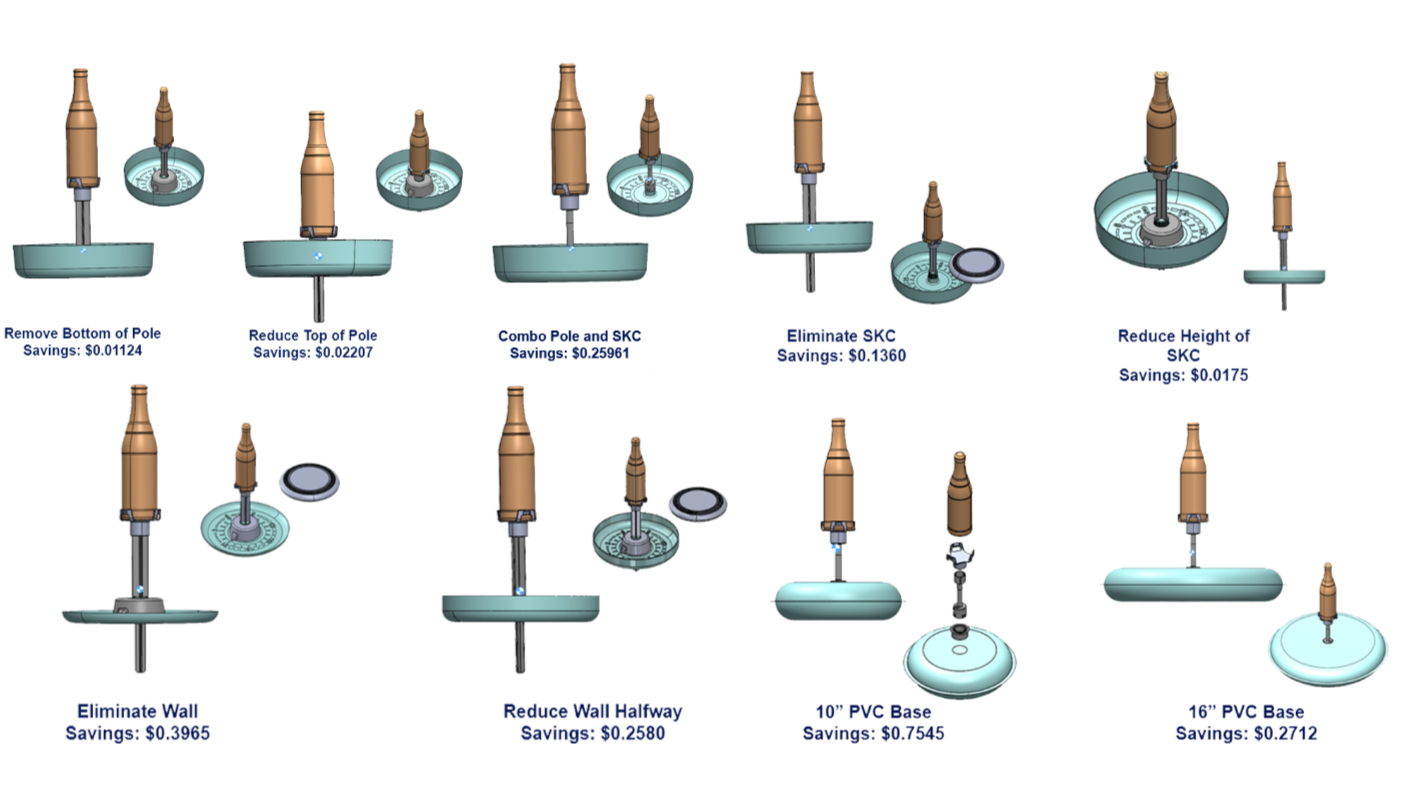

To find cost savings in this item while preserving the functionality, I built a menu of reduction options and worked through each one with my brand and design counterparts.

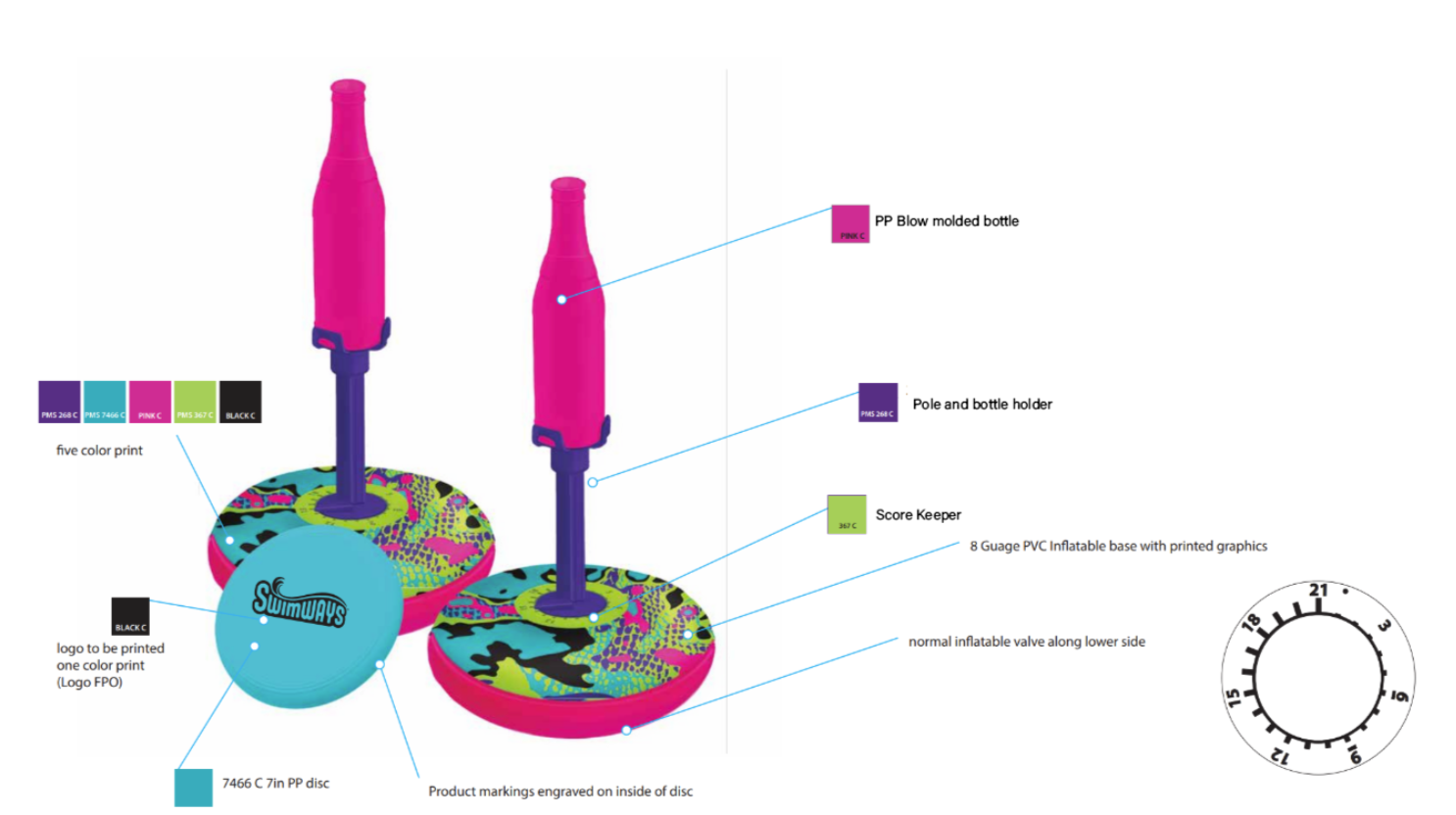

In the end, the team decided to move forward with the following changes:

Change the base from an injection molded “boat” to inflatable PVC

Reduce the height of the pole

Remove full color graphic prints on bottles and frisbee

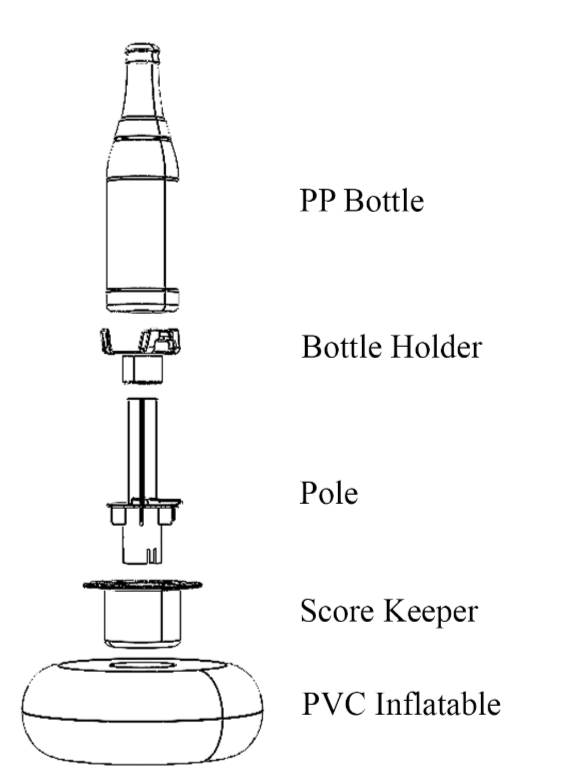

Refinement

Following collaboration with the brand and design team to establish product priorities, the structure underwent a refinement process for the updated structure. I closely collaborated with the manufacturing team in Asia to refine the CAD design, before proceeding to the creation of the initial prototypes.

The final cost based on this design came in at a 29% cost reduction compared to the needed 6.4%.

Shown on the right-hand side are a selection of images showcasing the final build.

Result

Upon the completion of the CAD design, I dedicated my efforts to iterate through multiple prototypes, to refine the product's fit and feel. The product lunched in spring 2023.